86-592-5659128 (to8016)

anna@xmydx.com86-592-5659128 (to8016)

anna@xmydx.com

2025-02-27 17:39:57

Where not to use Silicone?

While silicone is a highly versatile and durable material, it’s not suitable for every application. At our silicone products manufacturing factory, we believe in providing our clients with the best advice to ensure their projects succeed. In this article, we’ll explore situations where silicone may not be the optimal choice and discuss alternative solutions.

![]()

Silicone is known for its heat resistance, typically withstanding temperatures up to 230°C (446°F). However, in extreme heat applications, such as those exceeding 300°C (572°F), silicone can degrade or lose its properties. In such cases, materials like PTFE (Teflon) or ceramic may be more suitable.

![]()

While silicone is resistant to many chemicals, it can be damaged by strong acids (e.g., sulfuric acid) or alkalis (e.g., sodium hydroxide). In these environments, materials like Viton or EPDM rubber, which offer superior chemical resistance, are better alternatives.

(H2 - LSI Keyword: "Chemical Resistance of Silicone")

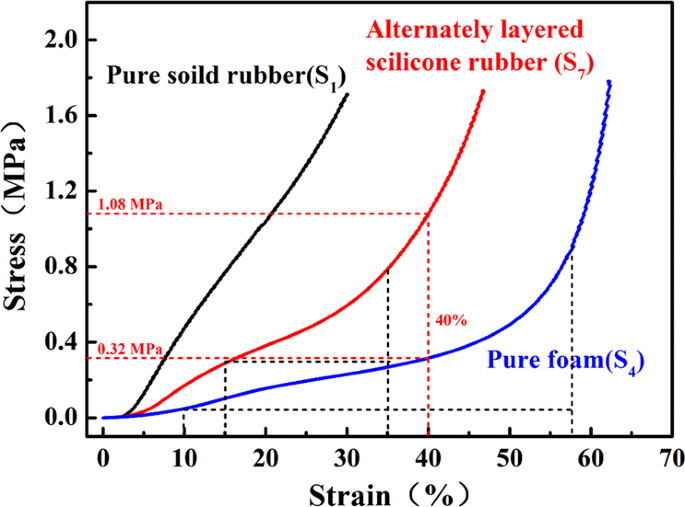

Silicone is flexible and elastic but lacks the tensile strength of materials like metal or high-performance plastics. In applications requiring high mechanical strength, such as heavy-duty industrial machinery, alternative materials like polyurethane or steel may be necessary.

While silicone is generally food-safe, it can absorb certain oils and solvents, leading to swelling or degradation. For example, silicone is not recommended for use with concentrated essential oils or highly acidic foods like vinegar or citrus juices. In such cases, materials like PTFE or stainless steel are preferable.

Silicone is soft and flexible, which makes it unsuitable for high-pressure hydraulic systems where materials like nitrile rubber or polyurethane are more appropriate. These materials offer the necessary durability and resistance to withstand extreme pressure.

While silicone is resistant to UV radiation, prolonged exposure to intense sunlight can cause it to degrade over time. For outdoor applications requiring long-term UV resistance, materials like EPDM rubber or vinyl are better choices.

![]()

Silicone’s flexibility makes it unsuitable for applications requiring rigidity or precise dimensions, such as structural components or precision machinery parts. In these cases, materials like polycarbonate or aluminum are more appropriate.

When silicone isn’t the right fit, here are some alternative materials to consider:

(H3 - LSI Keyword: "Alternatives to Silicone")

At our silicone products manufacturing factory, we understand the importance of choosing the right material for every application. If you’re unsure whether silicone is the best choice for your project, our team of experts is here to help. We can recommend alternative materials or custom solutions to meet your specific needs.

(CTA - Call-to-Action: "Contact Us for Expert Advice on Material Selection")

While silicone is a miraculous material with countless applications, there are situations where it’s not the best fit. Understanding its limitations and knowing when to use alternatives is key to ensuring the success of your project. If you’re looking for guidance on material selection or custom silicone products, don’t hesitate to reach out to us for professional advice.

© 2016 XIAMEN YIDEXIN SILICONE RUBBER INDUSTRIAL CO.,LTD Alle Rechte vorbehalten dyyseo.com

Online Contact

86-592-5659128 (to8016)

86-592-5659128 (to8016) anna@xmydx.com

anna@xmydx.com sallyliao1985

sallyliao1985 xmydx02

xmydx02 +86-13606037597

+86-13606037597top