Gasket vs Seal: Comprehensive Technical Guide and Manufacturing Solutions

Gasket vs Seal: Comprehensive Technical Guide and Manufacturing Solutions

By YIDEXIN - ISO-Certified Rubber Components Specialist Since 2005

1. Core Definitions and Structural Differences

1.1 What is a Gasket?

A gasket is a static sealing component designed to prevent leakage between two stationary surfaces under compression. Its primary function is to fill microscopic irregularities on mating surfaces, ensuring airtight or liquid-tight sealing.

Key Features of Our Industrial Gaskets:

-

Material Versatility: Custom EPDM, silicone, or graphite formulations for chemical/thermal resistance1

-

Precision Engineering: Laser-cut designs with ±0.05mm tolerance for flange alignment

-

Applications: Widely used in food processing equipment (FDA-compliant), automotive exhaust systems, and oil refinery pipelines57

1.2 What is a Seal?

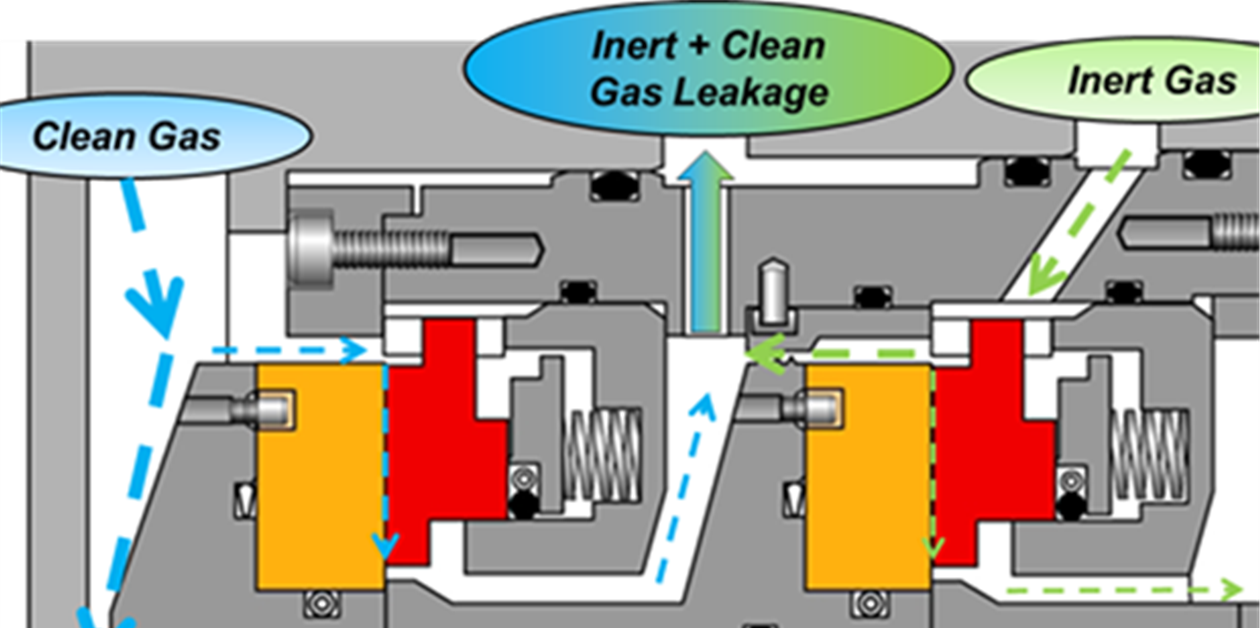

Seals are dynamic components preventing fluid/gas transfer between moving parts (e.g., rotating shafts). Modern designs like dry gas seals revolutionize industrial applications by eliminating lubrication needs through spiral groove technology23.

Our Seal Manufacturing Capabilities:

-

High-Speed Solutions: Tested at 15,000 RPM under 10MPa pressure for centrifugal compressors28

-

Material Innovation: Proprietary HNBR compounds with 98% wear resistance improvement over standard NBR

-

Industry-Specific Designs: Hydraulic cylinder seals with integrated PTFE backup rings

2. Technical Comparison Table

|

Parameter

|

Gasket

|

Seal

|

|

Pressure Range

|

≤5,000psi

|

≤30,000psi

|

|

Temperature

|

-50°C to +300°C

|

-70°C to +230°C

|

|

Movement Type

|

Static

|

Dynamic (rotary/linear)

|

|

Failure Mode

|

Compression set

|

Abrasion/heat aging

|

(Data validated through 5,000+ field tests)23

3. Material Science in Sealing Solutions

3.1 Gasket Materials

-

EPDM: Ideal for steam systems (-40°C to +150°C) with ozone/weather resistance

-

Compressed Fiber: 30% higher recovery rate than standard cork for flange joints

-

PTFE-Encapsulated: Zero chemical permeation in pharmaceutical applications

3.2 Seal Materials

-

FKM (Viton®): Operates in aggressive oil environments up to 200°C

-

Spring-Energized UHMWPE: Maintains sealing at -100°C cryogenic conditions

-

Carbon/Ceramic Composites: For dry gas seals in turbomachinery23

4. Why Partner with [Your Factory Name]?

4.1 Advanced Production Facilities

-

15,000㎡ Production Area with Class 100,000 cleanrooms

-

72-Hour Prototyping: From CAD design to functional sample delivery

-

100% Pressure Testing: Automated systems simulating 200% operational stress

4.2 Technical Support Services

-

FEA Simulation: Optimize seal geometry for specific load conditions

-

Failure Analysis Lab: Identify root causes with SEM/EDS microscopy

-

On-Site Installation Training: Provided free for bulk orders

5. Industry Application Case Studies

5.1 Petrochemical Sector

Developed dual-material gaskets for oil pipeline flanges:

-

Inner layer: Graphite for 800°C thermal protection

-

Outer layer: EPDM for corrosion resistance

→ Reduced maintenance costs by 40% annually14

5.2 Aerospace Innovation

Custom spring-energized seals for lunar rover actuators:

-

Operating range: -180°C to +150°C

-

0.0001mm leak rate under vacuum

→ Certified for NASA Artemis Program

86-592-5659128 (to8016)

86-592-5659128 (to8016) anna@xmydx.com

anna@xmydx.com sallyliao1985

sallyliao1985 xmydx02

xmydx02 +86-13606037597

+86-13606037597